Trash-2-Cash is an EU funded research project aiming to create new regenerated fibres from pre-consumer and post-consumer waste. It’s also pioneering a whole new way of developing materials.

But ‘why’?

One resource that’s becoming more abundant is waste. The idea of recycling textile waste has been popular for decades, but current mechanical methods give poor quality fabrics suitable only for industrial applications like insulation, and upcycling of pre-consumer textile waste into products is impossible to scale.

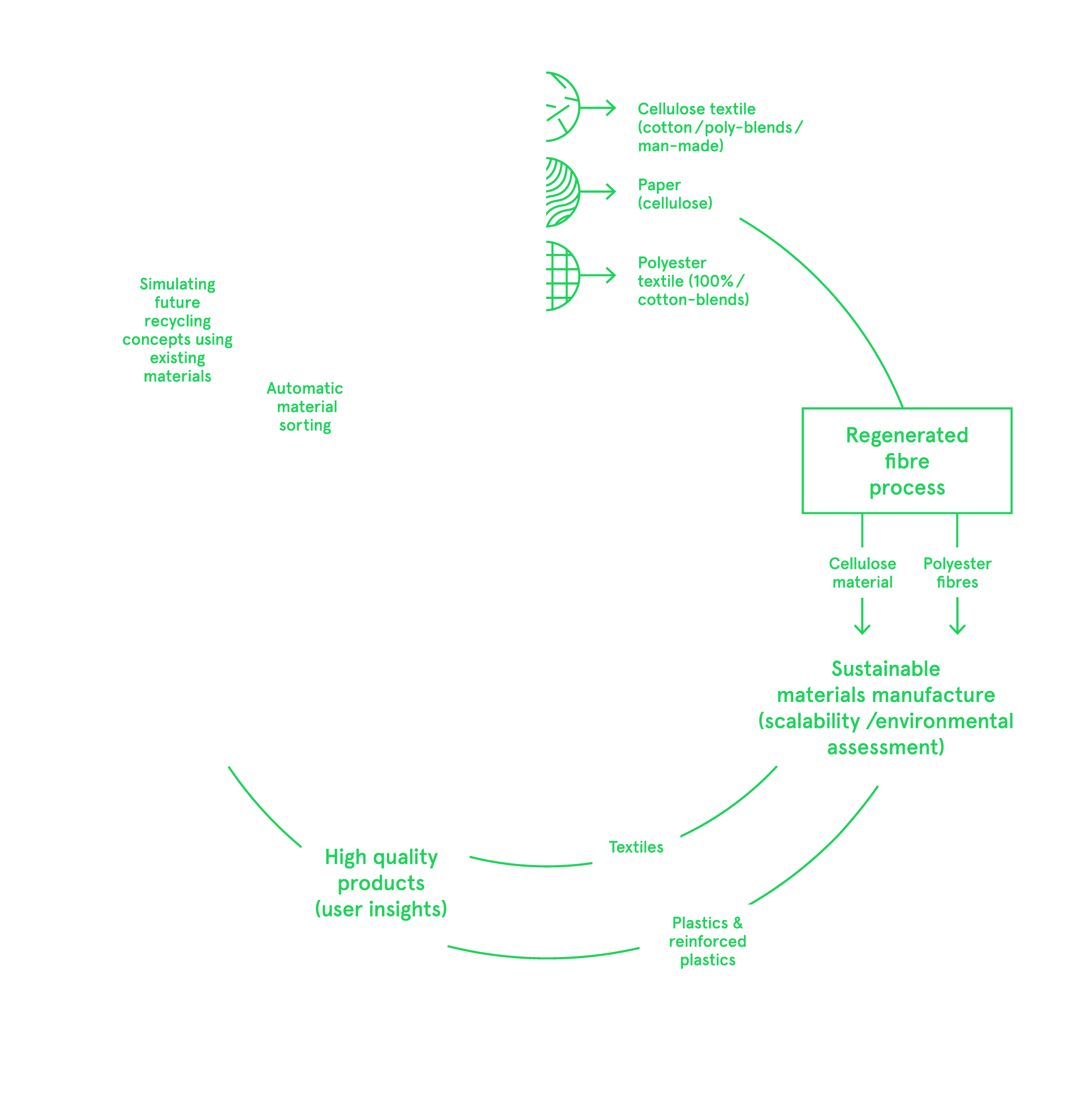

Trash-2-Cash (T2C) proposes a new model where paper and textile waste is recycled chemically - resulting in fabrics that are the same quality as new materials, to make products that are industrially replicable and infinitely recyclable.

Who is part of this challenge?

Designers, design researchers, scientists, raw material suppliers and product manufacturers from across Europe make up a cross-disciplinary consortium representing the whole product supply chain. Eighteen partners, from ten countries, are working together to address the challenge of designing high quality industrial materials from waste.

How long will the research take?

This is a three-and-a-half-year project.

- The first phase is cross-sectoral, with the whole group designing a wish list of fibre properties, then describing a vision for how the novel recycled materials will be used.

- In the second phase, material scientists produce samples of the new recycled cellulosic and polyester materials, and designers and industry produce product prototypes, based on consumer insights.

- In the final phase, academics reflect on the new collaborative Design Driven Material Innovation (DDMI) methodology, drawing upon their observations from the entire project.

What will be the outcomes?

- T2C aims to produce high quality materials and product prototypes from waste, offering companies in various industries (fashion, interiors, automotive and other luxury goods) new eco-fibre options.

- We also hope to influence how all novel materials are developed in the future through DDMI methodology. This new way of working will outline how science, design and industry can input into the process from beginning to end.